All shuffleboards are handmade in Eindhoven, Holland, in Shuffly’s own workshop. Our skilled team of craftsmen meticulously works together to ensure a high-quality product that not only looks good but also meets the highest standards of durability. We implement quality control throughout the entire production process; from the conceptualization to the manufacturing and the finishing touches.

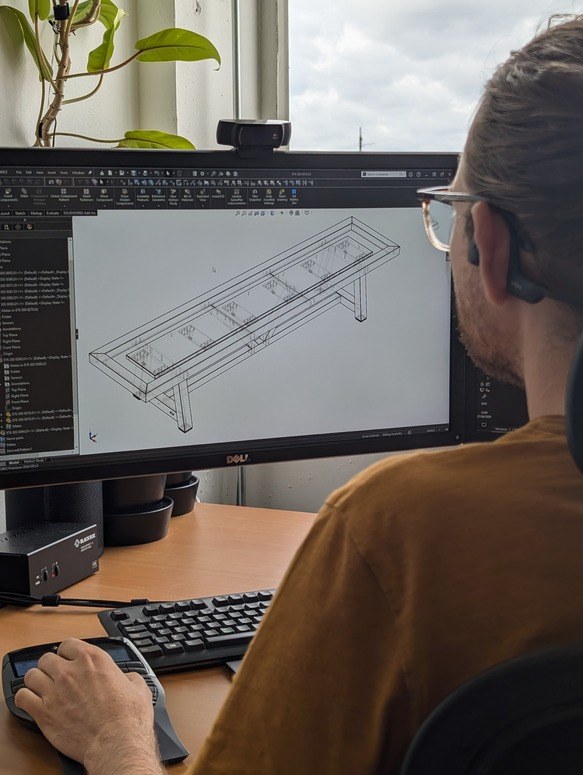

First, a 3D design is created with passion and meticulousness. Our mechanical engineer designs the shuffleboard in a computer-aided design program. This includes the:

Frame

The structure, including its frame and legs, is designed to be sturdy, stable, and durable.

Playing field

The shuffleboard’s playing field is made to be perfectly level, to ensure gameplay accuracy.

Electronic development

We don’t just make analog shuffleboards! Our Shuffle Showdown Shuffleboard is a high-tech electric shuffleboard using interactive machine vision. We developed a computer-controlled camera system to detect the pucks and display them on the shuffleboard screen for an electric game.

Branding and customization

Want to have a branded shuffleboard that matches your venue? We fully customize boards to your brand identity, logo, and color scheme for an integrated shuffle experience.

Then, suitable materials are sourced and ordered.

Wood selection

Premium oak wood is used to make the boards strong, moisture-resistant, and warp-resistant.

Metal and accessories

Metal is sourced for the frame and legs of the board. Other accessories such as LED lights are acquired to produce top-notch shuffleboard.

Coating

Premium epoxy is sourced to protect the wood and give the playing field a smooth appearance and level surface.

The shuffleboard is then completely made in Shuffly's own workshop.

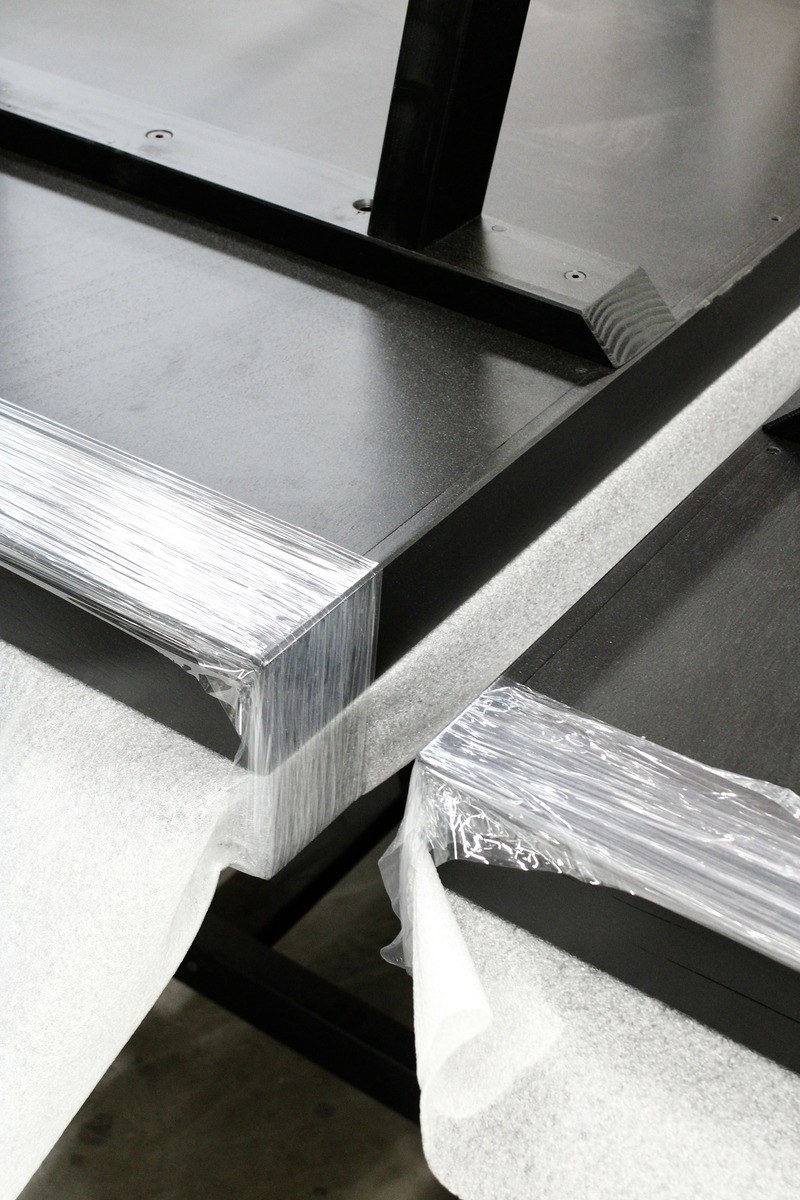

Metal assembly

Metal frames and components are assembled and welded in our Shuffly metal workshop.

Wood workshop

Rough wood is processed into a full-fledged wooden shuffleboard in the Shuffly wood workshop, which is equipped with all the necessary machines.

CNC Machining

Logos and graphics are laser engraved into the wooden frame and playing field with a CNC machine.

Epoxy

Epoxy work is done in a spray booth with good ventilation.

Light installation

Some shuffleboards like our Integrated LED Shuffleboard have modern LED lighting to capture attention and create a desired atmosphere. Pre-programmed light sequences and an easy-to-use app are provided.

Packaging

Shuffleboards are carefully packaged to ship the boards safely.

Delivery and installation

White-glove delivery is provided both nationally and internationally. The board is set up and adjusted by a professional so it’s ready for a fun game experience.

Manuals

A user manual is provided to help customers easily understand the game.

Maintenance

Shuffly provides maintenance guides and is, of course, available to assist when needed.

Want to know more about how shuffleboards are made? Or are you curious to see the process in detail? You can book an appointment to visit our workshop and showroom in Eindhoven, Holland. And let's not forget, there are plenty of shuffleboards to experience the fun of Shuffly for yourself!